Sealing engineered wood floors is a smart way to enhance their durability and protect against moisture, scratches, and wear. With a sealant, you create a barrier that helps preserve the floor's appearance and extends its lifespan. However, there are potential drawbacks, like altering the natural look or increasing maintenance. It's important to know when to seal and the best types of sealants to use. Discover more about maintaining and protecting your floors effectively.

Understanding Engineered Wood Floors

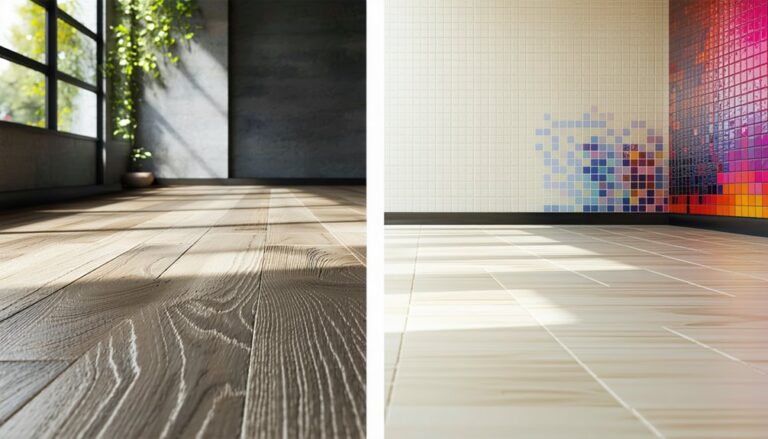

Engineered wood floors are a popular choice for many homeowners due to their durability and aesthetic appeal. These floors consist of multiple layers, with a top layer of real hardwood, providing the beauty of natural wood while enhancing engineered wood construction. This multi-layer composition allows for greater stability, making them less susceptible to warping and moisture damage compared to solid wood. You'll appreciate the engineered wood durability, which can withstand high traffic and daily wear better than traditional options. Additionally, their versatility in design means you can achieve your desired aesthetic without compromising on performance. With engineered wood floors, you're investing in a stylish and resilient sol solution that meets modern living demands while allowing for personal expression.

The Benefits of Sealing Engineered Wood Floors

While sealing engineered wood floors may seem like an extra step, it offers significant benefits that enhance both their longevity and appearance. By applying a sealant, you create a protective barrier against moisture, dirt, and spills, which can lead to degradation over time. The sealing benefits include increased resistance to scratches and stains, making your floors look newer for longer. Additionally, sealing contributes to durability enhancement, ensuring your engineered wood can withstand daily wear and tear. This not only preserves the visual appeal of your flooring but also reduces maintenance efforts. Ultimately, sealing your engineered wood floors is a smart investment that maximizes their lifespan and keeps them looking pristine, allowing you the freedom to enjoy your space without worry.

Potential Drawbacks of Sealing

While sealing engineered wood floors offers protection, there are potential drawbacks to contemplate. You may notice a reduced natural appearance, as the sealant can create a glossy finish that masks the wood's texture. Additionally, sealing can lead to increased maintenance requirements and risks of damage if not applied or maintained correctly.

Reduced Natural Appearance

Although sealing engineered wood floors offers protection against moisture and wear, it can also diminish their natural appearance. The sealant may create a glossy finish that obscures the wood's inherent texture, impacting its natural aesthetics. This glossy surface can reduce the visual appeal of your floors, making them look less authentic and more synthetic. If you value the organic look of your flooring, sealing might compromise that desired freedom in design. Additionally, the sealant can alter the color of the wood, resulting in a less vibrant display of its natural grain patterns. When considering whether to seal, weigh the benefits of durability against the potential loss of the genuine beauty that engineered wood floors provide.

Increased Maintenance Requirements

Sealing engineered wood floors can lead to increased maintenance requirements that homeowners should consider. Once sealed, you'll likely need to adjust your maintenance frequency to keep the floors looking their best. Regular cleaning becomes essential, as dirt and grime can accumulate more easily on sealed surfaces. You'll want to use specific cleaning methods that are compatible with the sealant, avoiding harsh chemicals that could damage the finish. This might include using pH-balanced cleaners and microfiber mops. Over time, the seal might wear down, necessitating reapplication, which adds to your upkeep. While sealing can enhance durability, it does require a commitment to ongoing maintenance that may not align with everyone's lifestyle preferences.

Potential Damage Risks

When considering the sealing of engineered wood floors, you should be aware of potential damage risks that could arise. While sealing can aid in damage prevention and moisture control, improper application can lead to several issues. For instance, a poorly sealed floor may trap moisture, resulting in mold growth. Additionally, certain sealants might alter the floor's appearance or texture, leading to aesthetic concerns.

| Potential Risk | Description |

|---|---|

| Moisture Trapping | Poor sealing can cause mold and mildew. |

| Aesthetic Changes | Sealants may affect the floor's finish. |

| Adhesive Failure | Improper sealing can weaken bond integrity. |

| Slippery Surfaces | Some sealants increase slip hazards. |

Understanding these risks helps you make informed decisions about sealing your engineered wood floors.

When to Consider Sealing Your Floors

If you're noticing signs of wear or damage on your engineered wood floors, it might be time to contemplate sealing them. The right sealing frequency can greatly enhance your floor's longevity. If you have high foot traffic or live in a humid environment, consider sealing more frequently—perhaps every 3 to 5 years. Pay attention to scratches, fading, or water stains; these can indicate that your floor's protective layer is compromised. Additionally, if your floors are looking dull or losing their luster, a sealant can restore their beauty and provide a barrier against further damage. Taking proactive measures not only preserves the appearance of your floors but also extends their lifespan, ensuring you enjoy their elegance for years to come.

Types of Sealants Suitable for Engineered Wood

When sealing engineered wood floors, it's essential to choose the right type of sealant. Water-based and oil-based sealants each have unique properties that can affect durability and appearance. Understanding these options will help you make an informed decision for your flooring needs.

Water-Based Sealants

Although many sealants are available, water-based sealants are particularly suitable for engineered wood floors due to their low VOC emissions and quick drying times. These sealants offer several water-based advantages, such as reduced odor during application and minimal environmental impact. When applying, you'll want to make certain the surface is clean and dry. Use a high-quality brush or roller for even coverage, and apply in thin coats to avoid pooling. It's essential to follow the manufacturer's instructions regarding drying times between coats. Typically, two to three coats are recommended for ideal protection. With the right application techniques, water-based sealants can effectively enhance the durability and appearance of your engineered wood floors, allowing you the freedom to enjoy your space worry-free.

Oil-Based Sealants

While water-based sealants are favored for their eco-friendly properties, oil-based sealants also play a significant role in the maintenance of engineered wood floors. These sealants provide excellent oil penetration, enhancing durability and resistance to moisture. When applying an oil-based sealant, use proper application techniques, such as a foam roller or brush, to guarantee even coverage. It's vital to allow adequate drying time between coats, typically 24 hours, for peak results. A well-executed application can create a rich, warm finish, enhancing the wood's natural beauty while offering protection from wear and tear. If you desire a long-lasting solution, consider oil-based sealants as a viable option for your engineered wood flooring needs.

Step-by-Step Guide to Sealing Engineered Wood Floors

Sealing engineered wood floors is a straightforward process that can greatly enhance their durability and appearance. First, choose the right sealing technique based on your engineered wood type—whether it's a water-based or oil-based sealant. Start by cleaning the floor thoroughly to remove dust and debris. Next, lightly sand the surface to guarantee proper adhesion. Apply the sealant using a roller or brush, working in small sections to achieve even coverage. Allow the first coat to dry completely, then lightly sand again before applying a second coat. After the final coat, let it cure for the recommended time to guarantee maximum protection. Following these steps will keep your engineered wood floors looking great for years to come.

Maintenance Tips for Sealed Engineered Wood Floors

To guarantee your sealed engineered wood floors remain in top condition, regular maintenance is essential. Start by using appropriate cleaning techniques, such as a microfiber mop and a gentle, pH-neutral cleaner. Avoid excessive water, as it can damage the seal and the wood beneath. For protective measures, place mats at entrances to catch dirt and debris, reducing wear on the surface. Additionally, consider using furniture pads to prevent scratches from heavy items. Periodically inspect the seal for wear, as timely attention can prevent more significant issues. By adhering to these maintenance tips, you'll ascertain your floors not only look great but also enjoy a longer lifespan, allowing you the freedom to enjoy your beautiful space.

How to Identify If Your Floors Need Sealing

To determine if your engineered wood floors need sealing, start by looking for visual signs of damage, such as scratches or discoloration. You can also perform a water resistance test by placing a few drops of water on the surface; if the water beads up, your seal is intact, but if it soaks in, it's time to reseal. Regular inspection will help maintain the integrity and longevity of your floors.

Visual Signs of Damage

While many homeowners appreciate the aesthetic appeal of engineered wood floors, it's important to recognize when they show signs of needing sealing. Look for visible scratches on the surface; these can compromise the protective layer, allowing moisture to penetrate. Discoloration is another critical indicator; fading or dark spots suggest that the finish is wearing thin and the wood beneath may be vulnerable. If you notice a dull appearance or areas that seem to absorb liquid rather than repel it, it's time to evaluate sealing. Regularly inspecting your floors for these signs can prevent further damage and prolong their life, ensuring your investment remains visually appealing and structurally sound. Keeping an eye on these factors is key to maintaining your floors.

Water Resistance Test

How can you determine if your engineered wood floors require sealing? Conducting a water resistance evaluation is essential. You can use several testing methods to assess your floors' ability to repel moisture. Here's how to perform the test:

- Place a few drops of water on the surface.

- Observe for absorption within 10 minutes.

- Check for discoloration or a change in texture.

- Repeat in different areas, focusing on seams.

- Note any previous water damage signs.

If the water penetrates quickly or leaves a mark, your floors likely need sealing. Regular evaluations will help maintain the integrity of your engineered wood, ensuring longevity and aesthetic appeal. Stay proactive to enjoy your beautiful floors without worry.

Alternatives to Sealing Engineered Wood Floors

Although sealing engineered wood floors offers protection, there are several effective alternatives that can maintain their appearance and durability. One option is using eco-friendly finishes, such as water-based polyurethane, which provides a protective layer without harmful chemicals. These sustainable options not only enhance the floor's longevity but also support a healthier indoor environment. Regular maintenance, like cleaning with a damp mop and using pH-neutral cleaners, can help prevent damage. Additionally, consider applying natural oils or waxes that nourish the wood while offering a degree of protection. By choosing these alternatives, you can preserve the beauty of your engineered wood floors without the commitment of sealing, allowing you to enjoy your space freely and responsibly.

Professional vs. DIY Sealing: What to Choose

When deciding between professional sealing and DIY sealing for your engineered wood floors, what factors should you consider? First, evaluate your skill level and comfortability with using professional tools. A DIY approach can be fulfilling but may lead to mistakes if you lack experience.

Consider these key points:

- Cost comparison: Professionals often charge more, but their work may save you money in the long run.

- Time commitment: DIY sealing can be time-consuming; professionals usually complete the job faster.

- Quality of finish: Professionals typically achieve a more uniform finish.

- Long-term durability: Expert sealing may offer better protection against wear.

- Warranty options: Many pros provide warranties that can offer peace of mind.

Choose wisely based on your priorities and resources.

Questions fréquemment posées

Can Sealing Affect the Appearance of My Engineered Wood Floors?

Sealing your engineered wood floors can indeed affect their appearance. With proper sealing, you'll experience significant sealing benefits, including enhanced durability and resistance to moisture. This process often leads to an appearance enhancement, as the sealant can enrich the color and sheen of the wood. However, it's crucial to choose the right sealant to guarantee that you maintain the desired aesthetic without compromising the floor's natural beauty.

How Long Does a Sealant Last on Engineered Wood Floors?

When considering sealant longevity for your engineered wood floors, think of it like a shield protecting a castle. Typically, a quality sealant lasts anywhere from 3 to 5 years, depending on your floor maintenance routine. Regular cleaning and avoiding excessive moisture can extend its life. If you notice wear or dullness, it's a sign that your protective layer may need renewing. Keeping your floors well-maintained guarantees they stand strong against the elements.

Is Sealing Necessary for All Types of Engineered Wood?

Sealing isn't necessary for all engineered wood types, but it can provide several sealing benefits. For instance, if you've chosen a lower-quality option, sealing can help protect against moisture and wear. Higher-quality engineered wood floors often come pre-finished with protective coatings, reducing the need for additional sealing. However, if you want to enhance durability and maintain appearance, applying a sealant can be a wise choice for any engineered wood flooring.

Can I Use Wax Instead of Sealant on Engineered Wood?

Using wax on engineered wood is like choosing a cozy blanket for a chilly night—it feels good, but it may not be the best fit. Wax offers benefits like a natural sheen and added moisture resistance, but it has drawbacks, too, such as difficulty in reapplication and potential buildup. If you want long-term durability and ease of maintenance, it's better to stick with a proper sealant designed for engineered wood.

Will Sealing My Floors Make Them Slippery?

Sealing your floors can potentially affect slip resistance, depending on the type of sealant used. If you opt for a sealant designed for engineered wood, it typically maintains good traction. However, certain finishes might make surfaces slick. For effective floor maintenance, always choose sealants that enhance grip. Regularly cleaning and maintaining your floors will also help keep them safe and functional. So, it's about finding the right balance for your specific needs.