You can refinish engineered floors, but your ability to do so depends largely on the thickness of the hardwood veneer. Because the veneer layer is thin, sanding must be light and precise to avoid damaging it. Engineered floors offer greater moisture resistance and stability than solid hardwood but allow fewer refinishing cycles. Proper refinishing requires specialized techniques and compatible finishes to restore appearance and durability. To understand the full process and alternative options, keep exploring these details.

Understanding Engineered Hardwood Flooring

Engineered hardwood flooring is a multi-layered product designed to provide the aesthetic appeal of solid hardwood while enhancing stability and resistance to moisture. You’ll find that its layered construction combines a hardwood veneer with plywood or high-density fiberboard cores, which considerably reduces expansion and contraction compared to solid wood. Understanding engineered flooring benefits means recognizing its durability in various environments, including basements and kitchens, where moisture can be an issue. When it comes to engineered floor maintenance, you should avoid excessive water and harsh chemicals, opting instead for damp mopping and manufacturer-recommended cleaners to preserve the finish. This approach allows you the freedom to enjoy hardwood’s beauty without the typical vulnerabilities of solid hardwood, making engineered flooring a practical, long-lasting choice for your living space.

Differences Between Engineered and Solid Hardwood

While both engineered and solid hardwood offer natural wood aesthetics, they differ considerably in construction, performance, and installation methods. Engineered hardwood consists of a thin veneer of real wood atop multiple plywood layers, whereas solid hardwood is a single piece of wood throughout. This fundamental difference impacts durability comparison and installation methods.

Engineered and solid hardwood differ in construction and durability, influencing performance and installation choices.

- Engineered hardwood is more dimensionally stable, resisting moisture and temperature changes better than solid wood.

- Solid hardwood generally allows for multiple refinishings due to its thicker wear layer.

- Installation of engineered floors often uses click-lock or glue-down methods, suitable for various subfloors.

- Solid hardwood typically requires nail-down installation on wooden subfloors.

Understanding these distinctions helps you select the floor that best fits your lifestyle and renovation freedom.

How Refinishing Works for Engineered Floors

Because engineered floors have a thinner wear layer than solid hardwood, refinishing requires specialized techniques and careful assessment of the floor’s thickness. You’ll need a light sanding process that preserves the veneer while removing surface scratches and old finish. This precision guarantees you maintain the floor’s structural integrity. After sanding, applying a compatible finish restores protection and enhances appearance. Understanding these refinishing benefits helps you extend your floor’s lifespan without costly replacement. To maximize results, follow maintenance tips like using gentle cleaning agents and avoiding excessive moisture. By doing so, you maintain your floor’s beauty and durability, giving you the freedom to enjoy a refreshed surface while protecting your investment with minimal disruption.

Factors Affecting Refinishing Eligibility

You’ll need to evaluate the engineered floor’s material composition, as some layers may limit how often refinishing is possible. Analyzing surface wear helps determine if the damage is superficial or deep enough to require sanding. Additionally, the thickness of the finish layer plays an essential role in deciding whether refinishing will be effective without compromising the floor’s integrity.

Material Composition Impact

Though Engineered Floors offer durability and aesthetic appeal, their material composition considerably influences whether they can be refinished. You must understand the layers and materials involved to gauge refinishing potential accurately. The top veneer layer’s thickness and quality dictate how many times refinishing can occur without compromising structural integrity. Material durability affects both the floor’s lifespan and its maintenance requirements; softer veneers wear faster, limiting sanding opportunities.

Key factors include:

- Veneer thickness: Thicker veneers allow more refinishing cycles.

- Core material: Stability varies between plywood, HDF, or MDF cores.

- Adhesive type: Some adhesives degrade with sanding.

- Surface finish: UV-cured coatings may demand specialized refinishing methods.

Knowing these elements helps you decide if refinishing preserves your floor’s freedom and longevity.

Surface Wear Assessment

Understanding the material composition sets the foundation, but evaluating surface wear is what ultimately determines if refinishing is feasible. You need to closely inspect the engineered floor’s surface durability, focusing on wear indicators such as scratches, dullness, and minor gouges. If these signs remain superficial and haven’t penetrated the wear layer, refinishing is typically an option. However, if wear indicators reveal exposed plywood layers or significant damage, the floor’s structural integrity is compromised, limiting your ability to refinish. Analyzing surface wear also involves considering environmental factors that accelerate degradation, like heavy foot traffic or moisture exposure. By accurately gauging surface durability and wear indicators, you can make an informed decision about whether your engineered floor can be restored to its original state or if replacement is necessary.

Finish Layer Thickness

Since the finish layer thickness directly impacts how many times an engineered floor can be refinished, accurately measuring this layer is critical. Without precise thickness measurement, you risk sanding through the veneer, compromising the floor’s integrity. Typically, engineered floors have a wear layer ranging from 0.6 mm to 6 mm, influencing their refinish potential.

Consider these factors when evaluating finish layer thickness:

- Thickness measurement methods, such as micrometers or specialized gauges

- Original wear layer specification from the manufacturer

- Visible signs of wear or sanding depth from previous refinishing

- Type of wood veneer and its durability under sanding

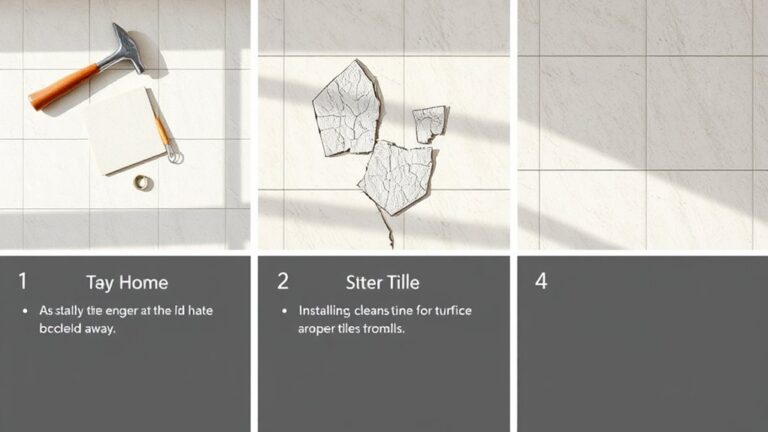

Step-by-Step Guide to Refinishing Engineered Floors

Before you begin refinishing, you need to accurately assess the thickness of your engineered floor’s wear layer to guarantee it can withstand sanding. Next, you’ll use specific sanding techniques tailored to engineered wood to avoid damaging the core layers. Finally, applying the right refinishing method will restore the floor’s surface while preserving its structural integrity.

Assess Floor Thickness

One critical step in refinishing engineered floors is accurately evaluating the floor thickness, as this measurement determines how many times the floor can be sanded without compromising its integrity. You’ll need a precise floor measurement to assess the veneer thickness, which directly affects your refinishing options. Start by identifying the thickness of the top wood layer, usually ranging from 0.6mm to 6mm. A thorough thickness evaluation helps avoid sanding beyond the veneer, preventing damage to the plywood core beneath.

Key points to take into account:

- Use a caliper or micrometer for accurate floor measurement.

- Check manufacturer specifications for veneer thickness.

- Measure at multiple points to guarantee consistency.

- Recognize that thinner veneers limit sanding opportunities and refinishing freedom.

Sanding and Refinishing Techniques

Understanding the thickness of your engineered floor’s veneer sets the stage for selecting the right sanding and refinishing approach. Begin with gentle sanding techniques, using a fine-grit sandpaper (around 120-150 grit) to avoid cutting through the veneer. Always sand with the grain to maintain wood integrity. Avoid aggressive sanding, which can compromise the veneer thickness and void warranties. After sanding, thoroughly clean the surface to remove dust and debris. Choose refinishing products specifically designed for engineered wood, such as water-based or oil-based finishes that enhance durability without damaging the layers beneath. Apply these products evenly, allowing proper drying time between coats. By following precise sanding techniques and using compatible refinishing products, you’ll restore your floor’s appearance while preserving its engineered structure and ensuring long-lasting freedom from premature wear.

Alternatives to Refinishing Engineered Flooring

Although engineered flooring can’t always be refinished like solid hardwood, there are effective alternatives to restore its appearance and extend its lifespan. When sanding and refinishing techniques aren’t viable, you can explore refinishing alternatives tailored for engineered flooring options. These methods help maintain your floor’s aesthetic without compromising its structural integrity.

Consider these practical approaches:

- Applying a high-quality floor polish or wax to conceal minor scratches and wear.

- Using specialized engineered floor repair kits for spot treatments.

- Recoating with a compatible polyurethane finish to refresh the surface layer.

- Replacing individual damaged planks instead of the entire floor.